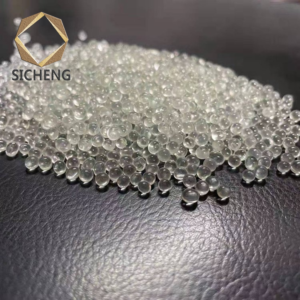

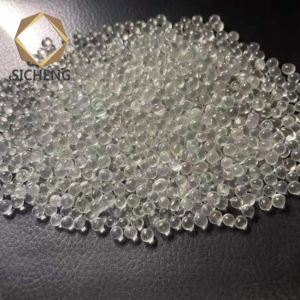

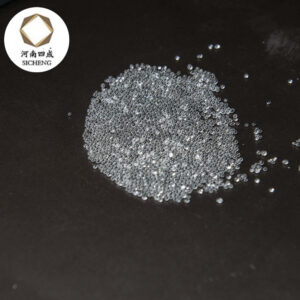

Grinding glass beads are small, spherical beads made from various types of glass (such as soda-lime, borosilicate, or zirconium silicate) that are used in grinding, milling, and polishing applications. They serve as grinding media in mechanical processes to break down, disperse, or refine materials.

Common Uses of Grinding Glass Beads:

Paint & Coatings Industry – Used in bead mills to disperse pigments and achieve fine particle sizes.

Pharmaceuticals & Cosmetics – Helps in homogenizing and reducing particle size in creams, ointments, and suspensions.

Ink Production – Used for grinding and dispersing ink pigments.

Ceramics & Minerals – Aids in wet or dry milling of ceramic powders and minerals.

Biotechnology & Cell Disruption – Used in bead mills to break open cells for DNA/RNA extraction.

Environmental Testing – Used in soil and sediment grinding for analysis.

Types of Grinding Glass Beads:

Soda-Lime Glass Beads – Economical, general-purpose grinding.

Borosilicate Glass Beads – More chemically resistant, suitable for harsh conditions.

Zirconium Silicate Beads – Higher density, better for fine grinding and high-impact milling.

Ceramic Beads – Sometimes used as an alternative for more durability.

Key Properties:

Size: Typically ranges from 0.1 mm to 3 mm in diameter.

Hardness: Varies based on glass composition (zirconium beads are harder).

Density: Affects grinding efficiency (higher density beads provide more impact force).

Chemical Resistance: Important for avoiding contamination in sensitive applications.

Advantages:

Uniform particle size reduction

Chemically inert (won’t react with most materials)

Reusable (depending on the process)

Smooth surface minimizes wear on equipment